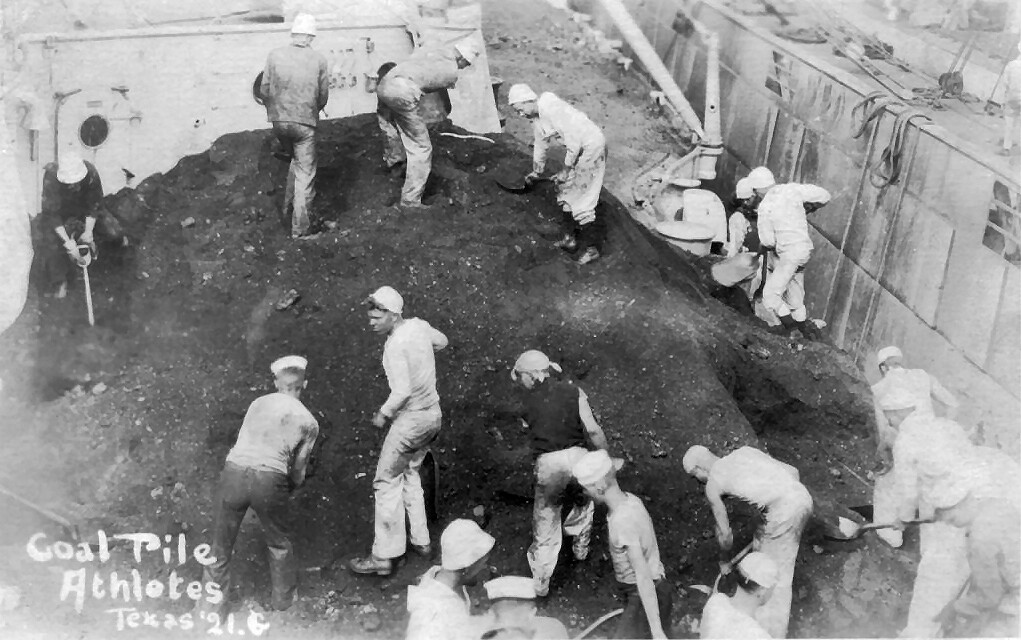

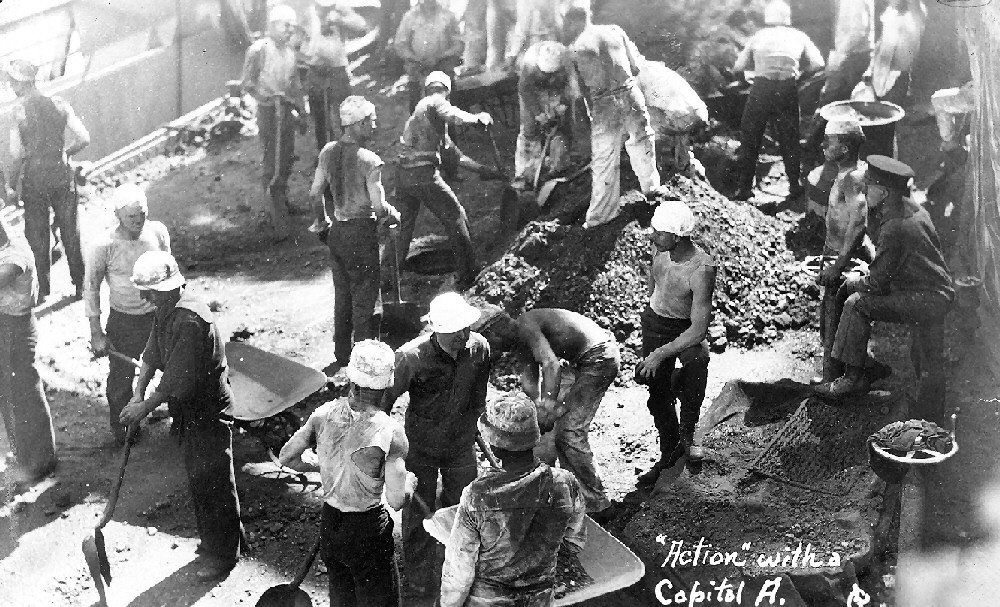

Once the coal was aboard, It took and army of sailors with shovels and wheel barrels to get the tons of coal into the twenty-eight 24 inch coal chutes for passing into the four storage levels below 2nd deck. The total per chute is approximately 2,110 cubic feet.